Description

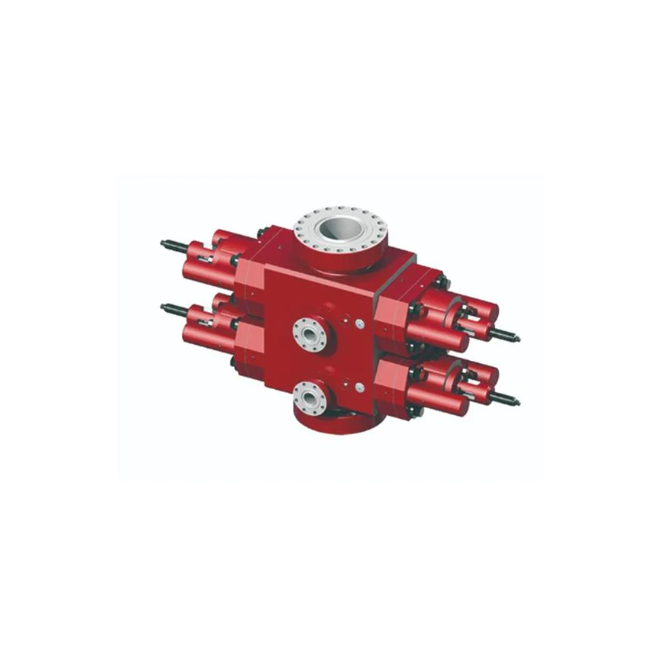

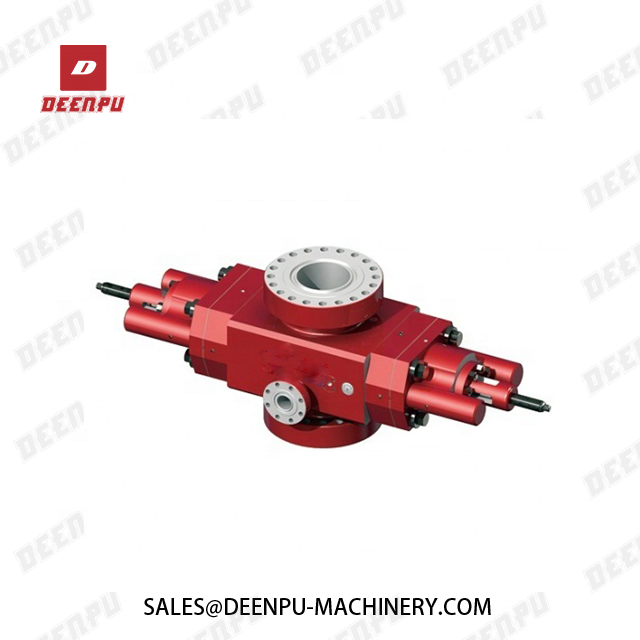

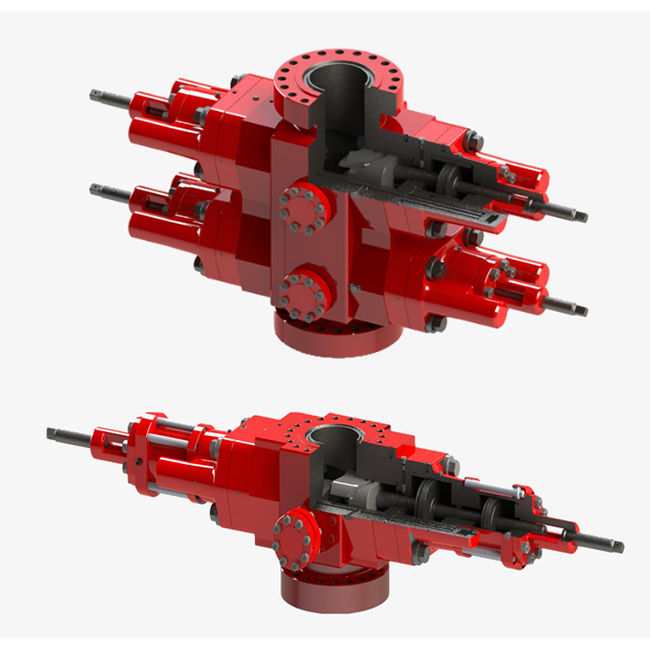

U Type Ram BOP

Structual Feature

● Pressurized components are forging matierals, having good strength and impact toughness, avoid the forging default.

● Middle flange uses combined seal, its switch is operated by hydraulic pressure, easy to change the ram.

● Equipped with auxiliary oil cylinder, compared with the traditional shear ram BOP, it has the function, smaller volume.

● Ram rubber is abundant, and use self-contained seal.

● Manual locking device belongs to the standard configuration, In the event of hydraulic loss, it can ensure that ram remains closed.

● Manual and hydraulic locking device and auxiliary oil cylinder can be equiped according to customer’s requirements flexibly, and easy to interchange.

● The internal shell of BOP resistant to low temperature can process pipeline, to make the steam flow inside the BOP, radiat heat. (for costumer’s option).

● The internal part of BOP resistant to high sulfer which contact the well liquid has Surfaced high nickel base alloy, which can achieve the highest levels of resistance to H2S and CO2.

Ram Assembly

● Pipe Ram

1. Top seal rubber 2. Ram body 3. Front seal rubber

U type Ram structure skech

Shear Ram

Shear ram can cut pipe the well, blindly close the wellhead, and also used as blind ram when there is no pipe in the well. The installation of shear ram is the same with the original ram.

● In the normal condition used as blind ram, in case of emergency, used as shear ram.

● Shear damper can be repeatedly cut pipe and not damage the blade, The weared the blade can be reused after the repair. Shenkai produces the shear ram with shear life in more than five times, Allowed to replace the sealing rubber.

● The ordinary ram blade is integrated with the ram body.

● The ram blade of BOP resistant to high sulfer is separated with the ram body, which is easy to change blade after blade damaged, and make the ram body be able to repeated use.

● The contact sealing surface between top seal of shear ram and blade is large, which effectively reduce the pressure on the rubber sealing surface, and prolong its life.

1. Down shear ram 2. Set srew 3. Left seal 4. Up blade

5. Top seal rubber 6. Up shear ram body

7. Blade seal 8. Set screw 9. Right seal 10. Down blade

Shear Ram Assembly Structure of U type Ram BOP resistant to high sulfer

1. Down shear ram body 2. Left seal rubber

3. Up shear ram body 4. Top seal rubber

5. Right seal rubber 6. Blade seal

Shear Ram Assembly Structure of U type Ram BOP

Variable Ram

Variable ram can be used to seal different diameter of pipe string. Variable ram is composed of variable ram, top seal, variable front seal. The installation of variable ram in the BOP is in the same as the common ram, don’t need to change any part of the BOP.

1. Variable Ram rubber 2. Ram body 3. Top seal rubber

Variable Ram Assembly Structure of U type Ram BOP

U Ram BOP Specification&Model

| Operating pressure (psi) |

Bore(in) | ||||||||

| 180-7 1/16 | 230-9 | 280-11 | 350-13 5/8 | 430-16 3/4 | 480-18 3/4 | 530-20 3/4 | 540-21 1/4 | 680-26 3/4 | |

| 140-20000 | \ | \ | U | \ | \ | \ | \ | \ | \ |

| 105-15000 | U | U | U | U | \ | \ | \ | \ | \ |

| 70-10000 | U | U | U | U | \ | U | \ | U | \ |

| 35-5000 | U | U | U | U | U | U | \ | U | \ |

| 21-3000 | U | U | U | U | U | \ | U | \ | U |

| 14-2000 | \ | \ | \ | \ | \ | \ | \ | U | \ |

Note:S Ram BOP Specification&Model

U represents U type ram BOP

| Specification&Model | Main Bore mm(in) |

Working Pressure MPa(psi) |

Oil quantity for opening (Single Cylinder) | Oil quantity for closing(Single Cylinder) | Ram Type | Ram Size (in) |

Dimension mm | weight kg | Recommended BOP code | |||||

| length | width | height | single | double | ||||||||||

| single | double | |||||||||||||

| 180(71/16 in)series | FZ18-352FZ18-35 | 180(71/16) | 35 | 4.6 | 4.6 | U | maximum5 1/2 | 2477(3273) | 550 | 736 | 1116 | 1870 | 3586 | C11.002 C11.00 |

| FZ18-702FZ18-70 | 180(71/16) | 70 | 4.6 | 4.6 | U | maximum5 1/2 | 2487 (3363) | 550 | 806 | 1216 | 2190 | 4095 | C20.002 C20.00 |

|

| FZ18-1052FZ18-105 | 180(71/16) | 105 | 4.6 | 4.6 | U | maximum5 1/2 | 2477(3273) | 550 | 832 | 1242 | 2215 | 4066 | C08.002 C08.00 |

|

| 280(11in)series | FZ28-352FZ28-35 | 280-11 | 35 | 10.6 | 10.8 | U | maximum8 5/8 | 3105 (4165) | 650 | 898 | 1380 | 3775 | 6915 | C06.002 C06.00 |

| FZ28-702FZ28-70 | 280-11 | 70 | 10.6 | 10.8 | U | maximum8 5/8 | 3035(4065) | 660 | 950 | 1430 | 3900 | 7115 | C09.002 C09.00 |

|

| FZ28-1052FZ28-105 | 280-11 | 105 | 10.9 | 11.1 | U | maximum7 5/8 | 3035(4396) | 820 | 1205 | 1840 | 6660 | 11750 | C01.002 C01.00 |

|

| FZ28-1402FZ28-140 | 280-11 | 140 | 30.1 | 26.6 | U | maximum6 5/8 | 3890(5104) | 1050 | 1470 | 2200 | 9525 | 16933 | C10.002 C10.00 |

|

| 346(135/8 in)series | FZ35-352FZ35-35 | 346(135/8) | 35 | 21 | 22 | U | maximum10 3/4 | 3647(4833) | 720 | 928 | 1501 | 5150 | 9750 | C21.002 C21.00 |

| FZ35-702FZ35-70 | 346(135/8) | 70 | 21 | 22 | U | maximum10 3/4 | 3707(4893) | 745 | 1115 | 1720 | 6020 | 10940 | C17.002 C17.00 |

|

| FZ35-1052FZ35-105 | 346(135/8) | 105 | 22.8 | 23.7 | U | maximum10 3/4 | 3957(5319) | 850 | 1340 | 2076 | 9310 | 16210 | C16.002 C16.00 |

|

| 540(211/4 in)series | FZ54-142FZ54-14 | 540(211/4) | 14 | 16.3 | 17.4 | U | maximum 16 | 4120(5800) | 1000 | 944 | 1638 | 7450 | 14420 | C25.002 C25.00 |

| 540(211/4 in)series | FZ54-352FZ54-35 | 540(211/4) | 35 | 51 | 56 | U | maximum16 | 4884(6364) | 1080 | 1300 | 2100 | 13720 | 26500 | C27.002 C27.00 |

| FZ54-702FZ54-70 | 540(211/4) | 70 | 51 | 56 | U | maximum16 | 4884(6364) | 1200 | 1742 | 2542 | 15718 | 29773 | C28.002 C28.00 |

|

| 680(263/4) | FZ68-212FZ68-21 | 680(263/4) | 21 | 36 | 37 | U | maximum20 | 5305(6646) | 1280 | 1214 | 1924 | 13300 | 24800 | C24.002 C24.00 |

| Note 1. BOP Testing pressure is 1.5 times of standard pressure | ||||||||||||||

| 2. Operating pressure is from 8.4Mpa to 10.5Mpa | ||||||||||||||

U Type Shear Ram Operating specification

| BOP Type | BOP model | Recommended BOP code | Cylinder Type | Specification of drill pipe |

| U | (2)FZ28-35 | (2)C06.00 | Normal cylinder | \ |

| (2)C06.00 | Cylinder with tandem booster | 5 1/2″ 24.7lb/ft G-105 PSL-3 | ||

| (2)FZ28-105 | (2)C01.00 | Normal cylinder | \ | |

| (2)C01.00 | Cylinder with tandem booster | 5 1/2″ 24.7lb/ft G-105 PSL-3 | ||

| (2)FZ 35-35 | (2)C21.00 | Normal cylinder | 5″ 19.5lb/ft G-105 PSL-3 | |

| (2)C26.00 | Cylinder with tandem booster | 5 1/2″ 24.7lb/ft S-135 PSL-3 | ||

| (2)FZ 35-70 | (2)C17.00 | Normal cylinder | 5″ 19.5lb/ft G-105 PSL-3 | |

| (2)C30.00 | Cylinder with tandem booster | 5 1/2″ 24.7lb/ft S-135 PSL-3 | ||

| (2)FZ 35-105 | (2)C16.00 | Normal cylinder | 5″ 19.5lb/ft G-105 PSL-3 | |

| (2)C23.00 | Large cylinder | 5 1/2″ 24.7lb/ft G-105 PSL-3 | ||

| (2)FZ 54-35 | (2)C27.00 | Normal cylinder | 6 5/8 ” 27.7lb/ft S-135 PSL-3 |

U Type Variable Ram Range

| BOP Type | BOP Model | Range of Variable Ram (in) | |||

| U | (2)FZ 28-35 | 2 7/8″-5″ | |||

| (2)FZ 28-70 | 2 7/8″-5″ | ||||

| (2)FZ 35-35 | 2 3/8″-3 1/2″ | 2 7/8″-5″ | |||

| (2)FZ 35-70 | 2 3/8″-3 1/2″ | 2 7/8″-5″ | |||

| (2)FZ 35-105 | 3 1/2″-5″ | 4 1/2″-5 1/2″ | |||

| (2)FZ 54-35 | 2 7/8″-5 7/8″ | ||||

Our company has been in the oil & gas drilling equipment industry for over more years, We are here to serve all your drilling equipment needs.

Our company has been in the oil & gas drilling equipment industry for over more years, We are here to serve all your drilling equipment needs.

Reviews

There are no reviews yet.