Description

FE 12 External Card Flange Processing Machine

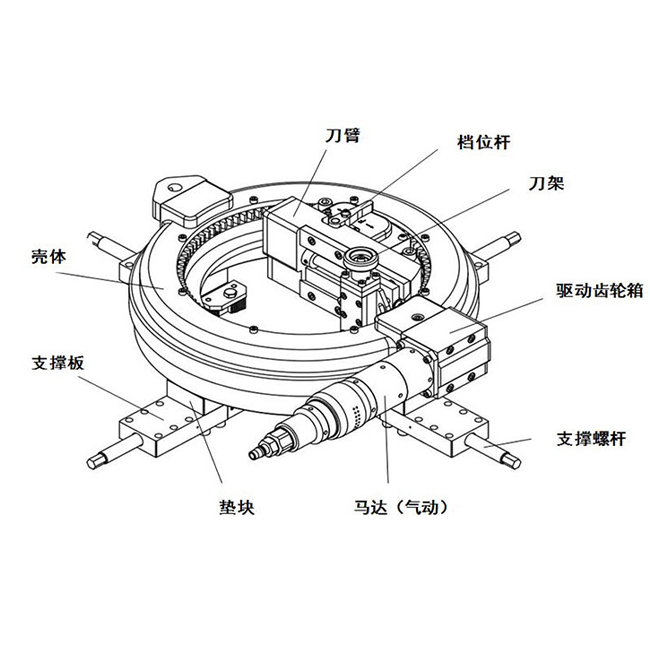

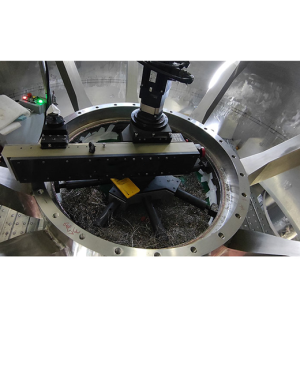

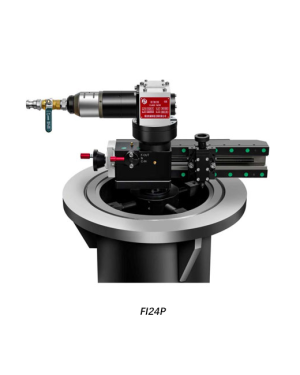

The biggest advantage of the FE 12 flange processing machine is that the processing range starts from scratch, adopts external card installation, and the equipment is clamped onto the outer wall of the flange pipeline, with a processing diameter range of Φ 0- Φ 305mm. The equipment adopts continuous spiral feed, and through gear switching, it can complete mirror processing and ASME B16.5 standard water lines. It can complete the processing of various sealing grooves such as FF, RF flange planes, and RTJ. This lightweight product is particularly suitable for sealing surface diameter Flanges below Φ300mm, especially if there is a welding layer or excessive welding deformation inside the pipeline

Equipment performance:

1. The main engine is made of aviation aluminum alloy material, which ensures strength while minimizing equipment weight. Equipment installation does not require lifting equipment.

2. The motor is parallel to the main engine, saving height and space.

3. High precision preloaded rotating bearings ensure machining plane accuracy.

4. The radial feed is automatic, and through gear switching, the machining of mirror ASME B16.5 standard water pipe lines can be completed.

5. Rotate the tool holder to adjust the angle and complete the processing of the RTJ sealing groove.

6. Compared with similar products in the market, the clamping range has been expanded to reach Φ 450mm.

7. Durable and high-quality aviation packaging boxes for easy transportation and storage.

| S/N. | project | parameter |

|---|---|---|

| 1 | Equipment model | FE12P |

| 2 | Clamping range | Φ50-450mm |

| 3 | machine range | Φ0-305mm |

| 4 | Tool holder travel | 40mm |

| 5 | Maximum speed | 45 rpm |

| 6 | Feed Speed | fine machining:0.125mm/rev |

| Ripple line:0.5mm/rev | ||

| 7 | Feed gear | 2-speed transmission |

| 8 | Pneumatic motor power | 1.0Kw (pressure 0.6Mpa) |

| 9 | Gas consumption | 1.0m3/min |

Our company has been in the oil & gas drilling equipment industry for over more years, We are here to serve all your drilling equipment needs.

Our company has been in the oil & gas drilling equipment industry for over more years, We are here to serve all your drilling equipment needs.

Reviews

There are no reviews yet.