Description

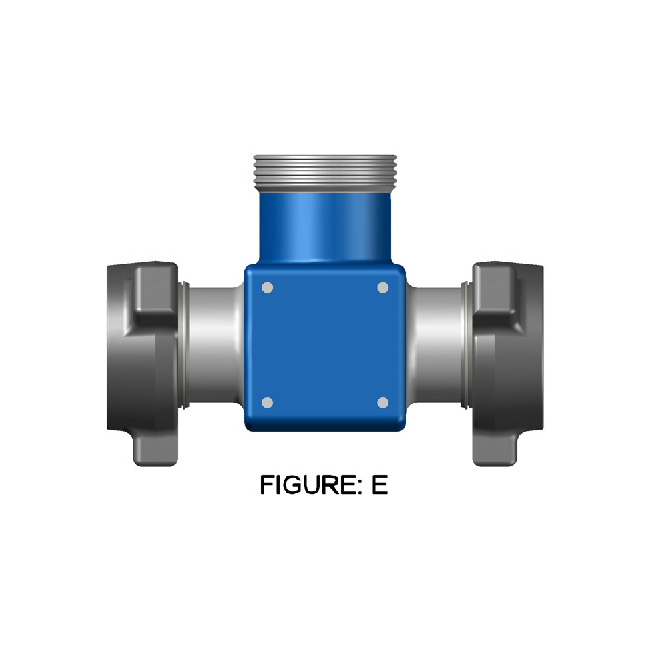

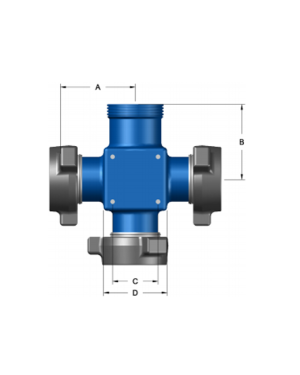

4 Inch 1002 Integral Fittings-FIGURE E

Connection Strength: Integral Fittings are made from one solid piece of metal providing more strength at the connection where it’s needed most.

Better Flow Geometry: The leading chamfers at the bore of DEENPU Integral Fittings creates less turbulence therefore reducing erosion.

Larger Wall Thickness: Our Integral Fittings have a larger wall thickness at the connection to allow the pipe a longer service life.

Replaceable Wingnuts: With a removable retainer ring, the wingnuts on DEENPU Integral Fittings can be replaced when necessary to allow continued service of the pup joint.

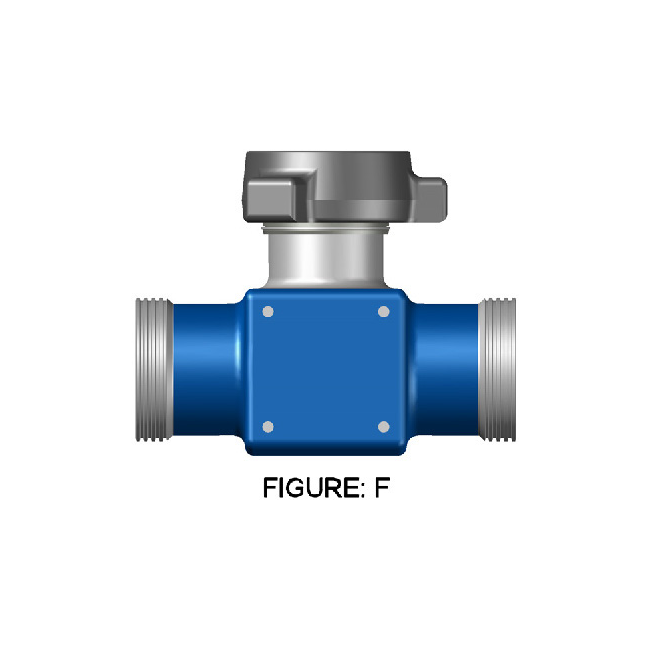

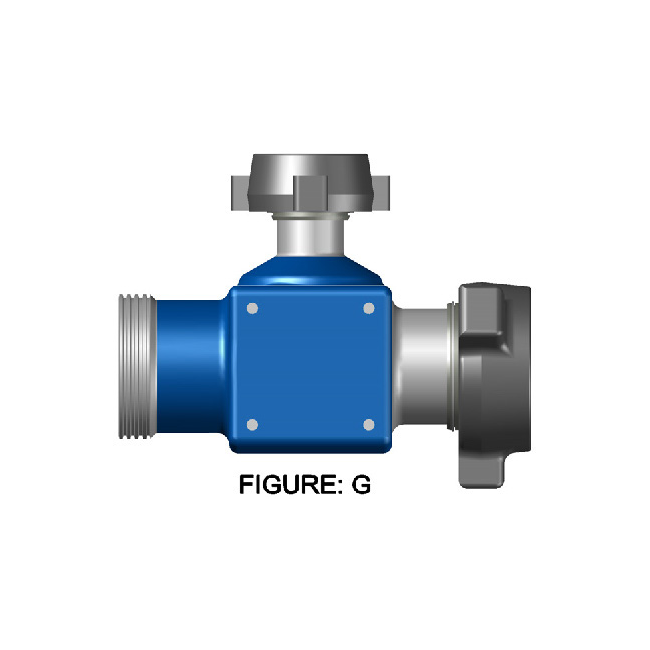

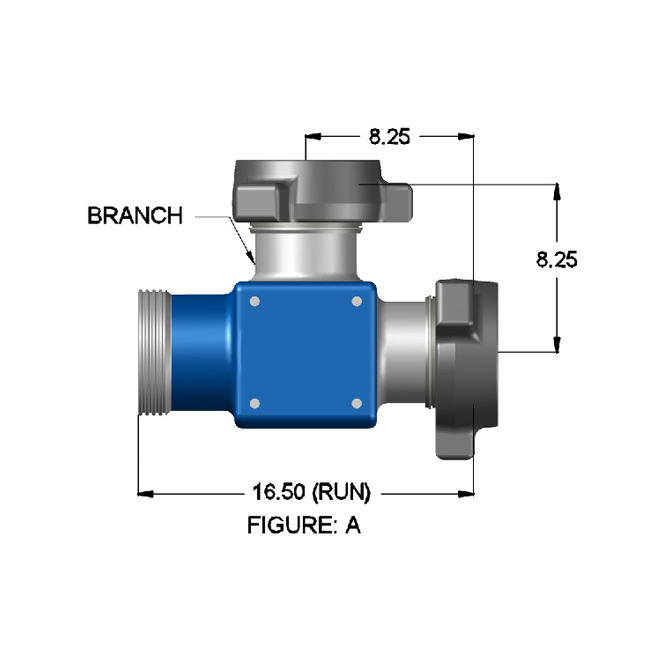

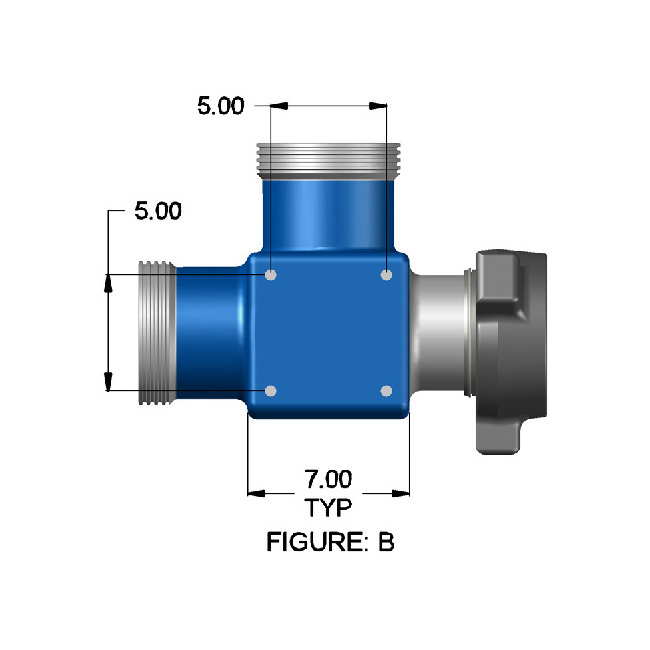

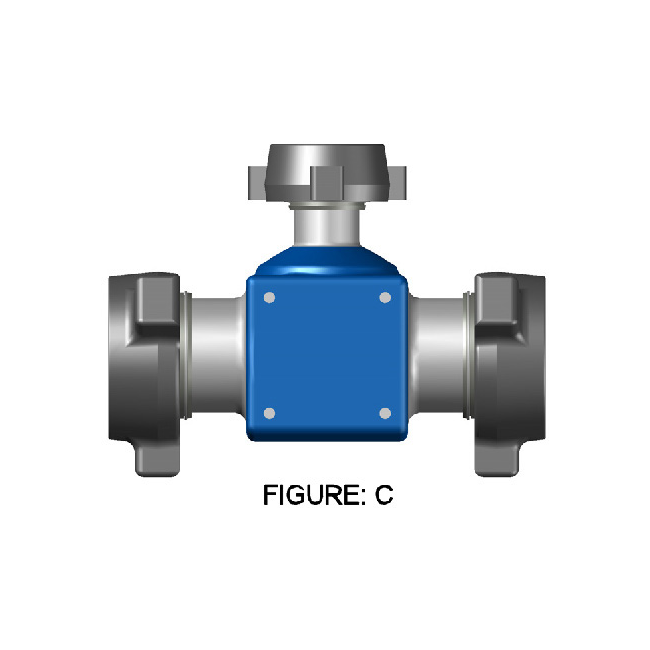

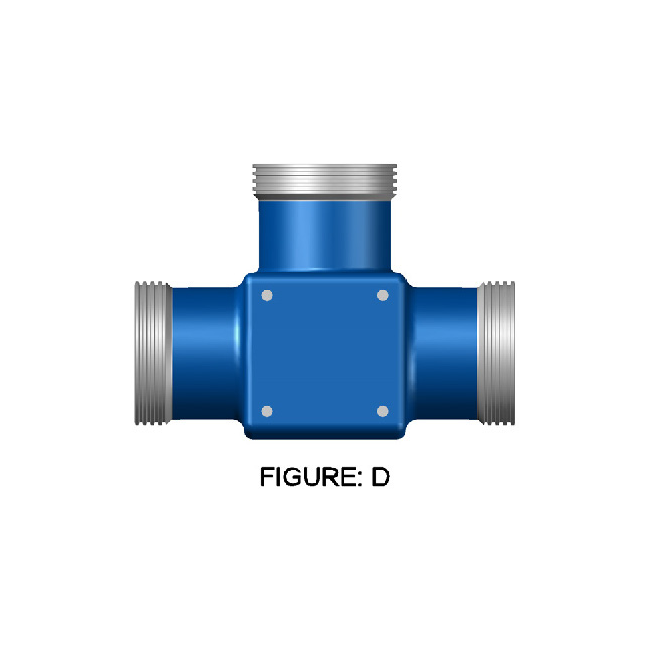

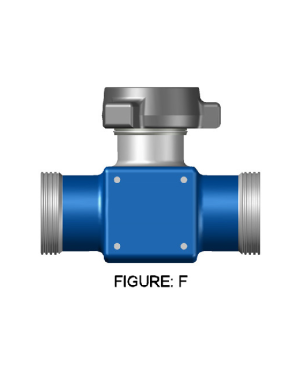

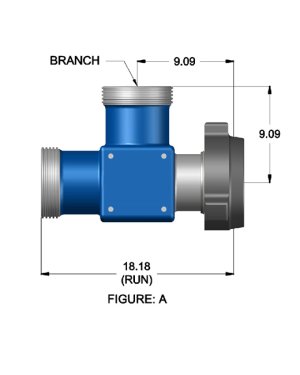

Below are some, not all 4″ 1002 TEE configurations offered. Custom 1002 to 1502 configurations available. Available for standard service only with a maximum allowable working pressure of 10,000 PSIG. Contact us for more information.

FIGURE: E

Run: 4” 1002 Male x 4” 1002 Male

Branch: 4” 1002 Female

| Rated Working Pressure | 69.0MPa~138.0Mpa (10,000psi~20,000psi) |

|

|---|---|---|

| Nominal Size | 1″, 2″, 3″, 4″ | |

| Temperature Rating | -29℃~121℃(PU), -46℃~121℃ (LU) | -20℉~250℉ (PU),-50℉~250℉(LU) |

| Service | Standard, Sour Gas | |

| Application | Fracturing, Cementing, Acidizing, Testing Lines | |

Our company has been in the oil & gas drilling equipment industry for over more years, We are here to serve all your drilling equipment needs.

Our company has been in the oil & gas drilling equipment industry for over more years, We are here to serve all your drilling equipment needs.

Reviews

There are no reviews yet.