Description

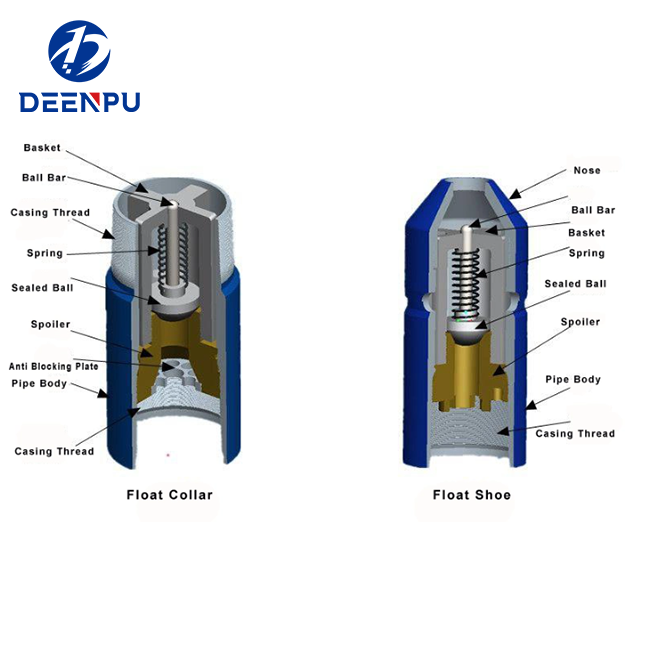

Float Collar & Float Shoe

Basic floating Equipment includes the Float Collar and Float Shoe:

The Float Shoe contains a backpressure valve that prevents fluids from entering the casing while the pipe is lowered into the hole and prevents cement from flowing back into the casing after placement, while enabling circulation down through the casing.

Float Collars are placed one to three joints above the Guide Shoe or Float Shoe. They provide a seat for the cement plugs, the bottom plug pumped ahead of the cement and the top plug behind the full volume of slurry. Once seated, the top plug shuts off fluid flow and prevents over-displacement of the cement. The space between the Float Shoe and the Float Collar provides a containment area to entrap the likely-contaminated fluids from the wiping action of the top cementing plug, securing the contaminated fluid away from the shoe where a strong cement bond is of primary importance. Float Collars include a backpressure valve and serve basically the same function as the Float Shoe.

- Used for the inner string cementing of large diameter casing.

- Displacement volume and cementation time are reduced.

- The valve is made with phenolic material and molded with high strength concrete. Both the valve and concrete are easily drillable.

- Excellent performance for flow endurance and back pressure holding.

- Single valve and double valve versions are available.

Type: Stab-in Type, Non-Rotating type, Standard Type

Connected Casing O.D.: 4-1/2 ~ 20 in (114 ~ 508 mm)

Thread type: BTC, LTC, STC and premium thread according to customer requirements

Steel grade: J55, K55, N80, L80, P110

Our company has been in the oil & gas drilling equipment industry for over more years, We are here to serve all your drilling equipment needs.

Our company has been in the oil & gas drilling equipment industry for over more years, We are here to serve all your drilling equipment needs.

Reviews

There are no reviews yet.