Description

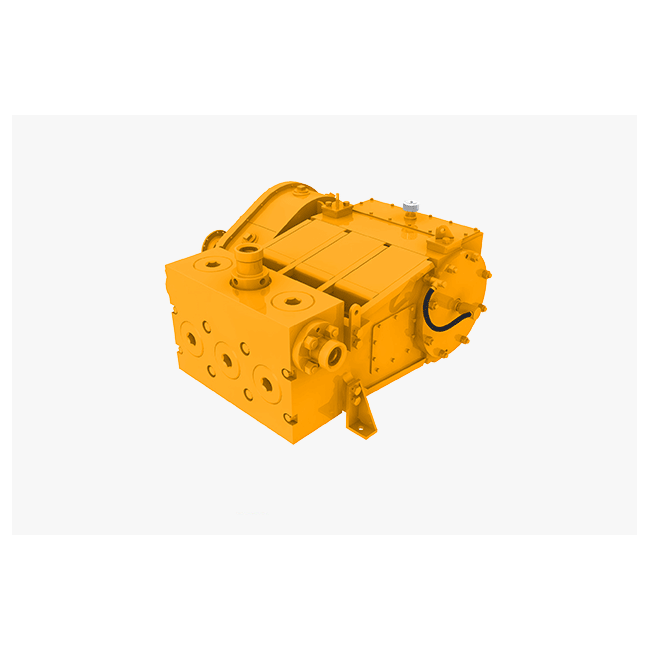

Triplex Plunger Pump

The plunger pump is an important device for the hydraulic system. It relies on the plunger to reciprocate in the cylinder to change the volume of the sealing working chamber to achieve oil absorption and oil pressure. The plunger pump has the advantages of high rated pressure, compact structure, high efficiency and convenient flow adjustment. Piston pumps are widely used in applications where high pressures, high flow rates, and flow rates need to be adjusted, such as hydraulic presses, construction machinery, and ships. The plunger pump is generally divided into a single plunger pump, a horizontal plunger pump, an axial piston pump and a radial piston pump.

Technical Specifications of Triplex Plunger Pump:

| English Units | Metric Units | Continuous | Intermittent | ||

| Stroke Length | 20 mm | Rated bhp | 4 HP | 5.6 HP | |

| Rated Rod Load | 1323 lb | 600 Kg | Maximum Speed | 450 rpm | 600 rpm |

| Pump Weight | 135 lb | 61 Kg | Minimum Speed | 100 rpm | 75 rpm |

| Oil Capacity | 0.32 gal | 1.2 L | Max. plunger size x stroke length. | 30×20 mm | |

| Max. Fluid Temp | 248 °F | 120 °C | Crankshaft extension Dia.x length | 28×42 mm | |

| Mechanical Efficiency | 90% | Keyway (width x depthxlength) | 8x4x38 mm | ||

Performance Ratings of Triplex Plunger Pump:

(Volumes indicated are displacement of incompressible fluid)

| plunger Dia. | L/RPM | Gal/

RPM |

Max.Press. | pump speed=90RPM | pump speed=200RPM | pump speed=300RPM | pump speed=450RPM | pump speed=500RPM | pump speed=600RPM | ||||||||||||||

| mm | in | Mpa | Psi | LPM | GPM | M3/h | LPM | GPM | M3/h | LPM | GPM | M3/h | LPM | GPM | M3/h | LPM | GPM | M3/h | LPM | GPM | M3/h | ||

| 11 | 0.43 | 0.006 | 0.002 | 63.0 | 9135 | 0.5 | 0.1 | 0.0 | 1.1 | 0.3 | 0.1 | 1.7 | 0.5 | 0.1 | 2.6 | 0.7 | 0.2 | 2.8 | 0.8 | 0.2 | 3.4 | 0.9 | 0.2 |

| 12 | 0.47 | 0.007 | 0.002 | 50.0 | 7250 | 0.6 | 0.2 | 0.0 | 1.4 | 0.4 | 0.1 | 2.0 | 0.5 | 0.1 | 3.1 | 0.8 | 0.2 | 3.4 | 0.9 | 0.2 | 4.1 | 1.1 | 0.2 |

| 13 | 0.51 | 0.008 | 0.002 | 40.0 | 5800 | 0.7 | 0.2 | 0.0 | 1.6 | 0.4 | 0.1 | 2.4 | 0.6 | 0.1 | 3.6 | 0.9 | 0.2 | 4.0 | 1.1 | 0.2 | 4.8 | 1.3 | 0.3 |

| 15 | 0.59 | 0.011 | 0.003 | 32.0 | 4640 | 1.0 | 0.3 | 0.1 | 2.1 | 0.6 | 0.1 | 3.2 | 0.8 | 0.2 | 4.8 | 1.3 | 0.3 | 5.3 | 1.4 | 0.3 | 6.4 | 1.7 | 0.4 |

| 17 | 0.67 | 0.014 | 0.004 | 25.0 | 3625 | 1.2 | 0.3 | 0.1 | 2.7 | 0.7 | 0.2 | 4.1 | 1.1 | 0.2 | 6.1 | 1.6 | 0.4 | 6.8 | 1.8 | 0.4 | 8.2 | 2.2 | 0.5 |

| 19 | 0.75 | 0.017 | 0.004 | 20.0 | 2900 | 1.5 | 0.4 | 0.1 | 3.4 | 0.9 | 0.2 | 5.1 | 1.3 | 0.3 | 7.7 | 2.0 | 0.5 | 8.5 | 2.2 | 0.5 | 10.2 | 2.7 | 0.6 |

| 21 | 0.83 | 0.021 | 0.005 | 16.0 | 2320 | 1.9 | 0.5 | 0.1 | 4.2 | 1.1 | 0.2 | 6.2 | 1.6 | 0.4 | 9.3 | 2.5 | 0.6 | 10.4 | 2.7 | 0.6 | 12.5 | 3.3 | 0.7 |

| 24 | 0.94 | 0.027 | 0.007 | 12.5 | 1813 | 2.4 | 0.6 | 0.1 | 5.4 | 1.4 | 0.3 | 8.1 | 2.2 | 0.5 | 12.2 | 3.2 | 0.7 | 13.6 | 3.6 | 0.8 | 16.3 | 4.3 | 1.0 |

| 27 | 1.06 | 0.034 | 0.009 | 10.0 | 1450 | 3.1 | 0.8 | 0.2 | 6.9 | 1.8 | 0.4 | 10.3 | 2.7 | 0.6 | 15.5 | 4.1 | 0.9 | 17.2 | 4.5 | 1.0 | 20.6 | 5.4 | 1.2 |

| 30 | 1.18 | 0.042 | 0.011 | 8.0 | 1160 | 3.8 | 1.0 | 0.2 | 8.5 | 2.2 | 0.5 | 12.7 | 3.4 | 0.8 | 19.1 | 5.0 | 1.1 | 21.2 | 5.6 | 1.3 | 25.4 | 6.7 | 1.5 |

| Brake Horsepower Required | 0.8 | 1.8 | 2.7 | 4(Continuous work) | 4.5 | 5.6 | |||||||||||||||||

Our company has been in the oil & gas drilling equipment industry for over more years, We are here to serve all your drilling equipment needs.

Our company has been in the oil & gas drilling equipment industry for over more years, We are here to serve all your drilling equipment needs.

Reviews

There are no reviews yet.